Associate Professor Yuen Yong and her research team at Griffith University have introduced an innovative method known as PIDES—pulsating in situ dried electro stretching—for fabricating microneedles. The method produces needles under 1 mm in length, specifically designed to painlessly penetrate the skin’s outer layer and facilitate effective drug delivery.

Existing fabrication methods such as micro moulding, wet etching and 3D printing are often complex, expensive and may not be ideal for some temperature sensitive drugs.

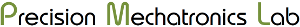

The fabrication process employs pulsed electrohydrodynamic forces generated between two metallic plates to stretch polymer droplets into tapered, conical forms. As the solvent evaporates, the material solidifies into rigid microneedles with sharp tips optimized for minimally invasive application.

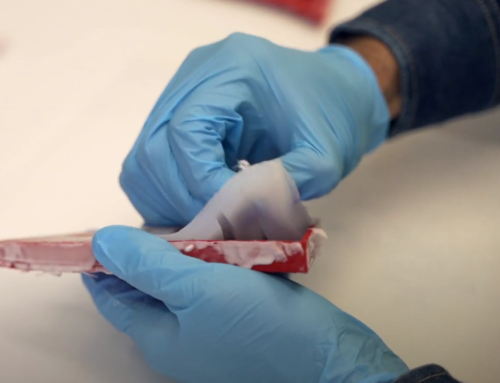

Experimental validation involved testing on agarose gel and pig skin substrates, where the microneedles demonstrated sufficient mechanical strength and reliable skin penetration. Furthermore, the team encapsulated curcumin—a model drug compound—within the microneedles and observed a controlled, time-dependent release profile, underscoring the system’s biocompatibility and therapeutic potential.

The PIDES technique is low cost and scalable, allowing multiple microneedles to be fabricated without compromising quality.

The study ‘Fabrication of Microneedles by Pulsating In Situ Dried Electrostretching for Transdermal Drug Delivery’ has been published in Small Methods.